Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

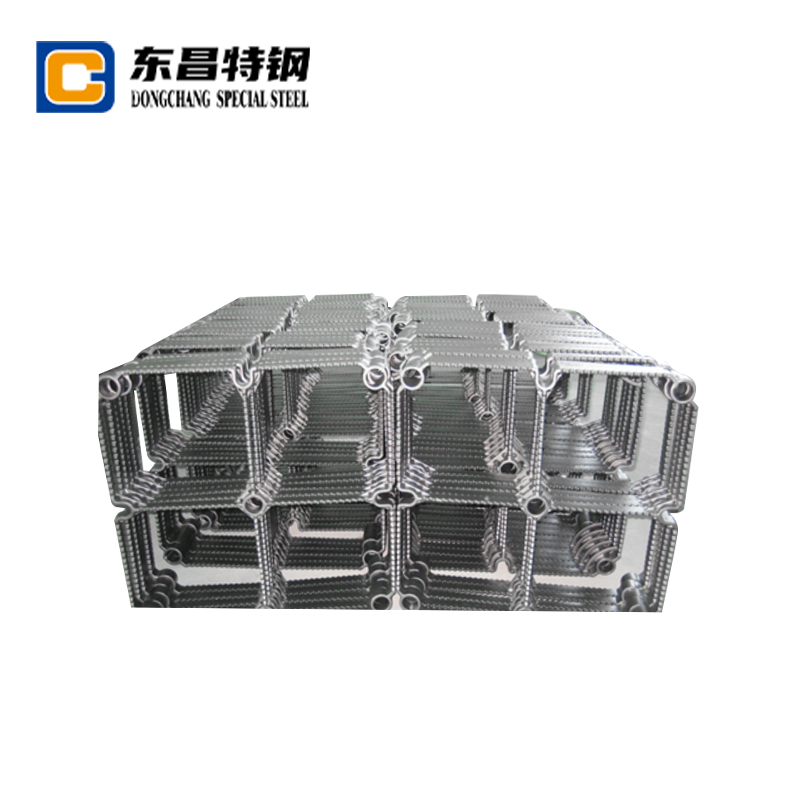

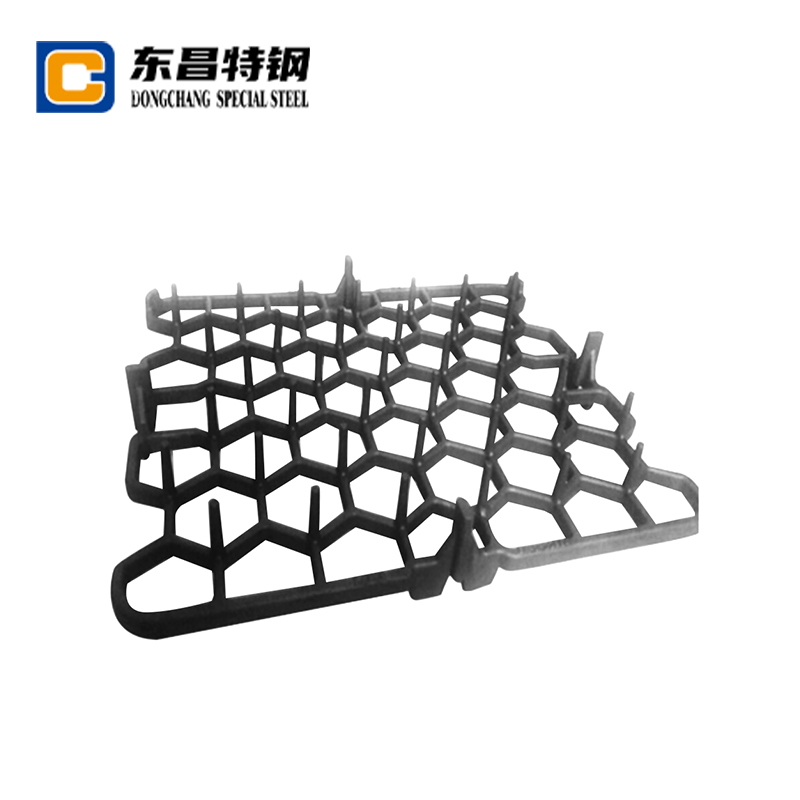

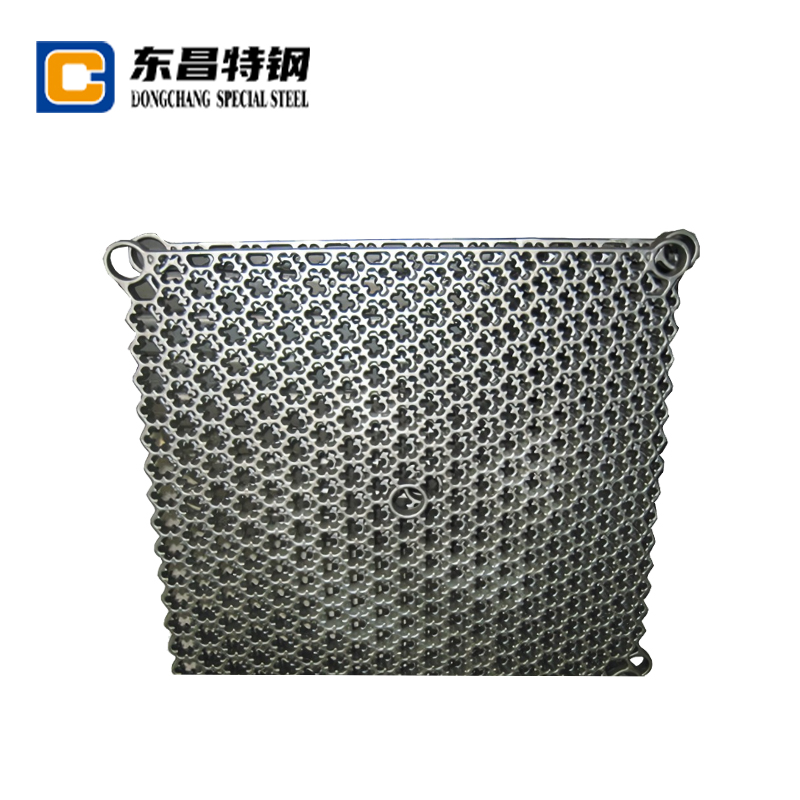

Heat Resistant Steel Material Frame Castings are castings made of high temperature resistant alloy steel materials. These castings are usually used to withstand mechanical loads, thermal expansion and thermal shock in high temperature working environments. Compared with ordinary steel, heat resistant steel has better oxidation resistance, corrosion resistance and high temperature strength, and can maintain stable performance under long-term high temperature conditions.

1. High temperature strength

The ability of heat resistant steel materials to maintain strength at high temperatures is one of its most important characteristics. Ordinary steel is prone to plastic deformation and strength reduction at high temperatures, while heat resistant steel can maintain its strength and hardness in high temperature environments and is not prone to breakage.

2. Oxidation resistance and corrosion resistance

High temperature steel usually adds elements such as chromium, molybdenum, and tungsten. These elements can effectively improve the oxidation resistance of steel, so that it can still maintain good durability under the action of corrosive media such as high temperature gas and steam.

3. Good thermal stability

High temperature resistant steel materials have excellent thermal stability, can withstand large temperature differences, and reduce stress concentration caused by thermal expansion.

4. High thermal conductivity and thermal shock performance

Due to the high thermal conductivity of high temperature resistant steel, it can effectively and evenly disperse heat and reduce local overheating. At the same time, it can also withstand strong thermal shock and avoid brittle fracture of the material.

Main applications of high temperature resistant steel frame castings

High temperature resistant steel frame castings are widely used in equipment and structures that need to operate for a long time under high temperature conditions. The following are some typical application areas:

1. Petrochemical industry

In petroleum refining and chemical engineering, high temperature resistant steel frame castings are widely used in high temperature reactors, heat exchangers, piping systems and other equipment. These equipment operate in high temperature, high pressure, and corrosive environments, and require very durable materials to ensure long-term stable operation.

2. Power industry

In the power industry, especially in power plants, high temperature resistant steel materials are often used in key equipment such as boilers, steam turbines, and steam pipes. These equipment not only need to withstand high temperature environments, but also must withstand steam erosion and mechanical stress.

3. Aerospace

Aircraft engines, rocket engines and other aerospace equipment all require the use of high-temperature resistant materials, especially the frame structure. High-temperature resistant steel materials can effectively avoid the impact of high temperature on the structure.

4. Metallurgical industry

Furnaces, heating devices and casting equipment in the metallurgical industry also widely use high-temperature resistant steel frame castings, especially when smelting and processing metals at high temperatures, these equipment need to withstand extremely high temperatures and oxidizing environments.

5. Automobile manufacturing

Especially for high-temperature parts such as high-performance engine parts and exhaust systems, high-temperature resistant steel materials can provide stronger heat resistance and corrosion resistance, extending the service life of automotive parts.

Advantages of high-temperature resistant steel frame castings

The use of high-temperature resistant steel frame castings can bring many advantages, mainly including the following aspects:

1. Improve the reliability and service life of equipment

High-temperature resistant steel materials can maintain their physical properties in extreme environments, thereby effectively reducing the frequency of equipment failures caused by material fatigue or damage and extending the service life of equipment.

2. Reduce maintenance costs

Due to the strong oxidation resistance and corrosion resistance of high temperature steel, equipment made of these materials can usually reduce damage caused by corrosion or thermal expansion, thereby reducing the frequency of maintenance and replacement, saving long-term operating costs.

3. Improve product performance

The thermal stability and strength of high temperature steel materials enable them to maintain excellent mechanical properties at higher temperatures, which helps to improve the overall performance of high temperature equipment, such as improving efficiency and reducing energy consumption.

4. Environmental protection and energy saving

The long-term stability of high temperature steel materials means that equipment can operate in an efficient state, reducing resource waste and energy loss, which meets the needs of modern industry for environmental protection and energy conservation and emission reduction.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878