Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

The structural design of the Heat Treatment Tray is the key to ensuring its durability and stability in high temperature environments. This design process combines knowledge from multiple disciplines such as materials science, mechanical engineering, and thermodynamics to create a product that can withstand extreme temperatures while maintaining structural integrity.

Material selection and layout

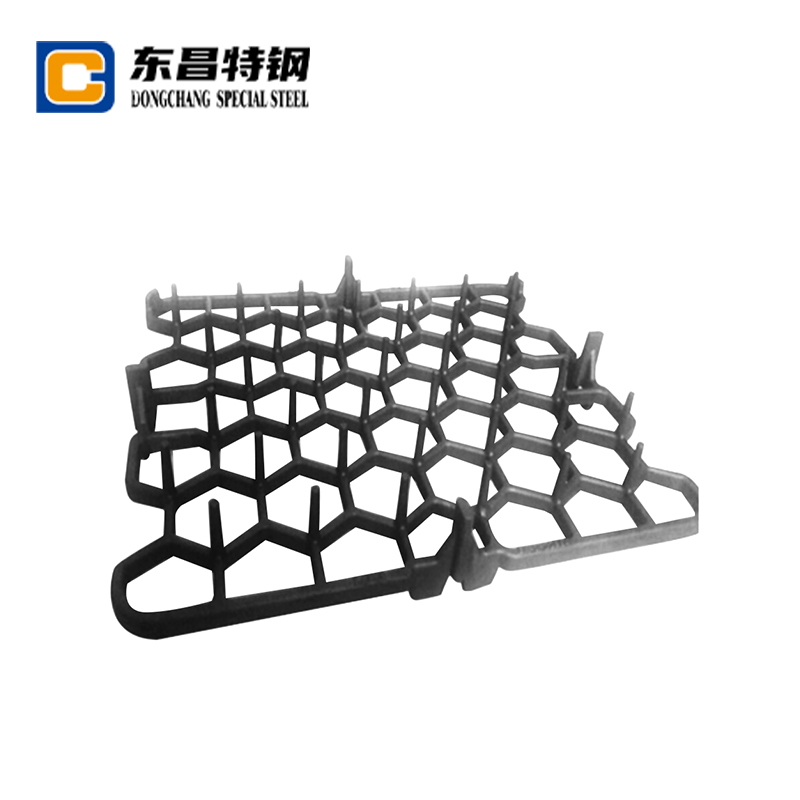

The selection of materials is the cornerstone. Heat Treatment Trays are usually made of high-temperature, high-strength, and corrosion-resistant materials such as stainless steel, nickel-based alloys, or ceramic composites. These materials can maintain stable physical and chemical properties at high temperatures and are not prone to softening, deformation, or oxidation. In addition, the layout of materials also needs to be carefully considered to ensure that higher-quality materials are used in key areas to withstand higher thermal and mechanical stresses.

Structural design optimization

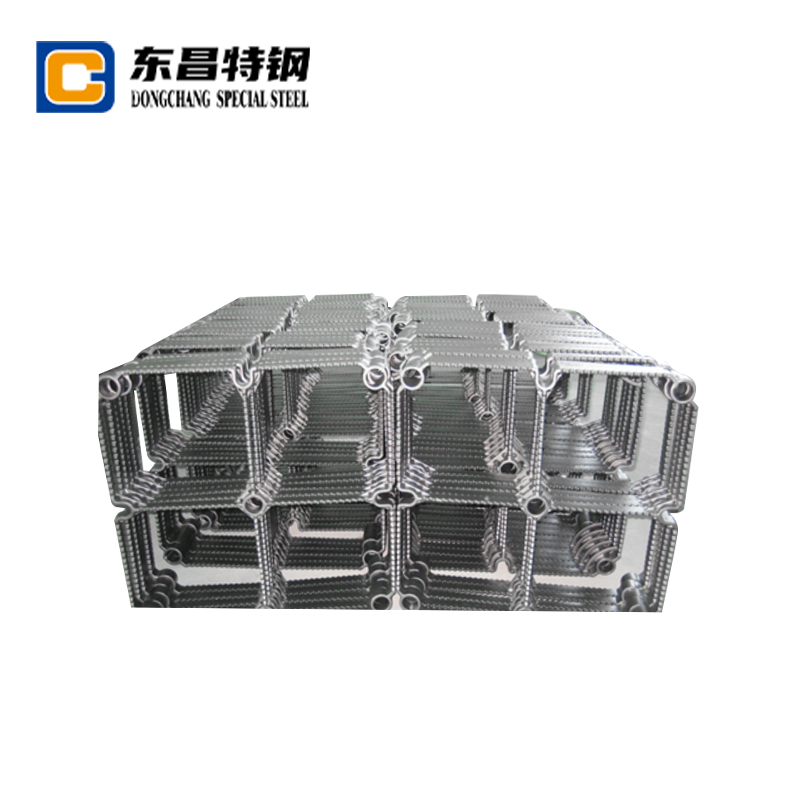

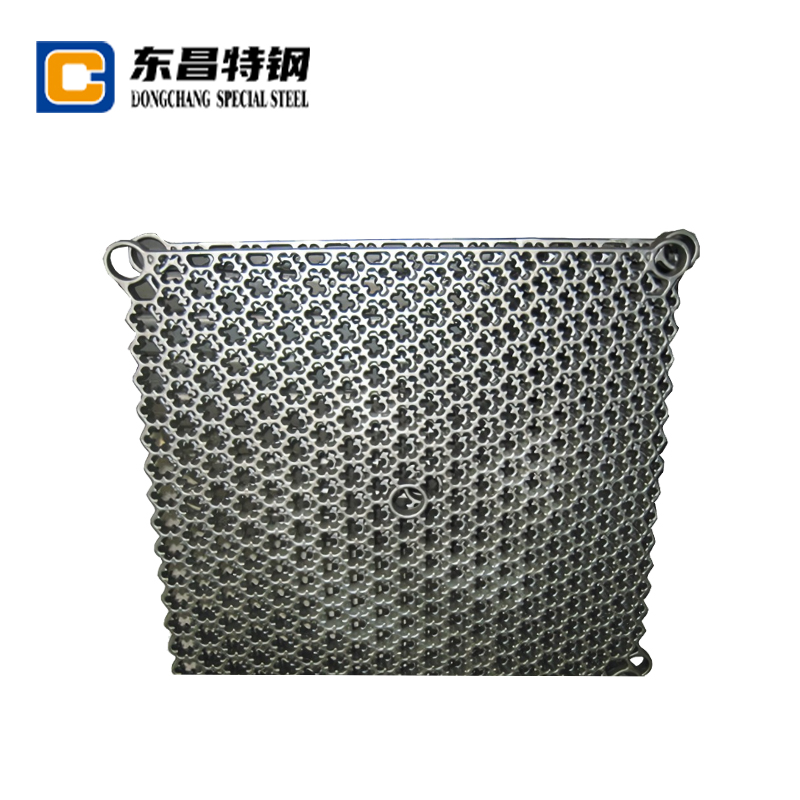

Thickness and reinforcement ribs: In order to enhance the structural strength of the tray at high temperatures, the wall thickness of the tray will be appropriately increased during design, and reinforcement ribs will be set at key locations. These reinforcement ribs can not only effectively disperse the load, but also reduce deformation caused by uneven thermal expansion. At the same time, a reasonable wall thickness design can also help improve the thermal insulation performance of the tray and reduce heat loss.

Ventilation hole design: Ventilation holes are an indispensable element in the design of heat treatment trays. They not only help the convection of hot air and promote uniform heat distribution, but also reduce heat accumulation at the bottom of the tray and reduce thermal stress. The size, shape and distribution of the vents need to be accurately calculated and optimized according to the specific application scenario to ensure the best heat transfer effect and structural stability.

Thermal expansion management: Since materials will expand thermally in high temperature environments, the design of Heat Treatment Tray must consider thermal expansion management. Through reasonable structural design, such as reserving thermal expansion gaps and using flexible connectors, it can be ensured that the tray can expand freely without restraint at high temperatures, thereby avoiding damage caused by concentrated thermal stress.

Precision manufacturing and quality control

The manufacturing process of Heat Treatment Tray is also an important part to ensure its durability and stability. The use of precise processing equipment and processes can ensure that the dimensional accuracy, surface finish and internal quality of the tray meet the design requirements. In addition, strict quality control processes, including raw material inspection, production process monitoring and finished product testing, are also key to ensuring stable and reliable quality of trays.

Maintenance and Care

Although the durability and stability of the Heat Treatment Tray have been fully considered during its design and manufacturing, reasonable maintenance and care are still important measures to extend its service life. Regularly checking the appearance, size and performance of the tray, and timely discovering and dealing with potential problems such as cracks and deformation, can prevent the problem from expanding and affecting the use effect. At the same time, keeping the tray clean and dry, and avoiding corrosion or damage to the tray by impurities such as oil and dust at high temperatures are also important aspects of maintaining the stability of the tray.

The structural design of the Heat Treatment Tray successfully meets the durability and stability requirements in high temperature environments through careful selection of materials, optimization of structural layout, use of precision manufacturing processes, and strengthening of maintenance and care. These design concepts and measures not only improve the performance and reliability of the heat treatment tray, but also provide strong support for the development of the heat treatment industry.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878