Xinghua Dongchang Alloy Steel Co., Ltd (formerly known as Xinghua Dongchang Alloy Steel Plant) is a manufacturer of China steel and alloy utility castings products. We were established in August 2006 and are located in the National Torch Plan China Alloy Steel Casting Base.

With the in-depth pursuit of the "dual carbon" goal worldwide, the industrial field is undergoing a profound green transformation. In this context, as a key equipment, the improvement of the energy conservation and emission reduction performance of Heat Resistant Steel Loading Frame is particularly important. As one of the important strategies for energy conservation and emission reduction, lightweight design has shown many technical innovations and improvements in heat-resistant steel loading frames.

Necessity of lightweight design

Lightweight design aims to reduce energy consumption and carbon emissions by reducing the weight of Heat Resistant Steel Loading Frame. For heat-resistant steel loading frames, lightweighting can not only reduce the energy consumption of the equipment itself, but also further reduce energy consumption during transportation, installation and operation, and improve overall efficiency. In addition, lightweighting can also help improve the flexibility and maintainability of equipment and extend its service life.

Materials Science and Technology Innovation

Application of Advanced Materials:

With the advancement of materials science, a series of new lightweight and high-strength materials have been developed and applied to Heat Resistant Steel Loading Frame. These materials, such as titanium alloy, aluminum alloy, ceramic composite materials and high-performance heat-resistant alloy, not only have excellent high temperature resistance, but also have low density, which makes the loading frame significantly reduce weight while maintaining strength.

Optimization of Material Microstructure:

Through advanced heat treatment process and microstructure control technology, the grain structure and phase composition of heat-resistant steel can be improved, and the specific strength and specific stiffness of the material can be increased, so as to achieve lightweight Heat Resistant Steel Loading Frame while maintaining or improving mechanical properties. For example, the use of fine grain strengthening and precipitation strengthening can significantly improve the comprehensive performance of the material.

Structural Design Innovation

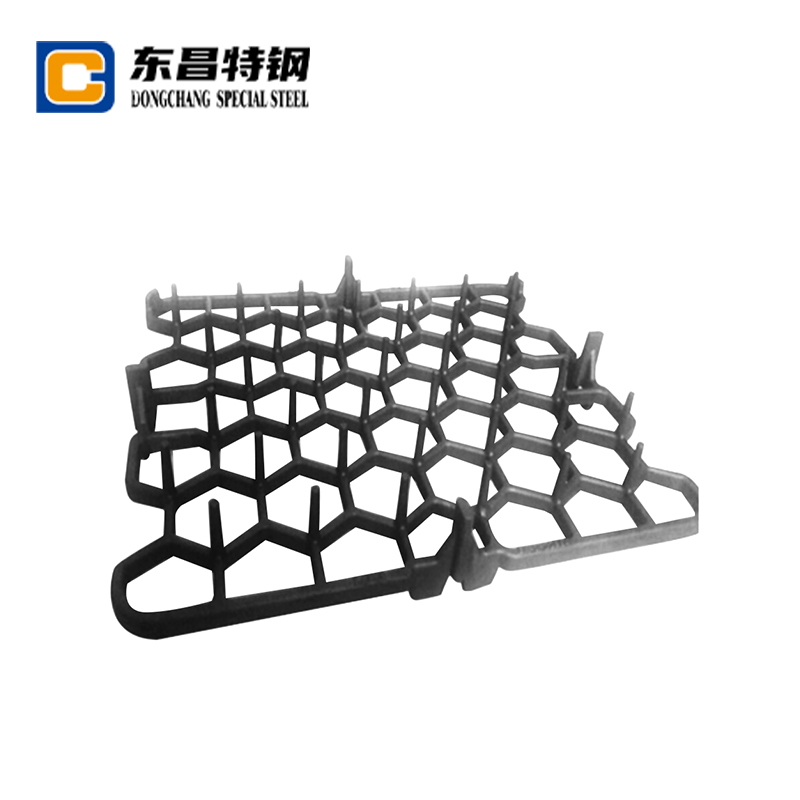

Topology Optimization and Simulation Analysis:

Using computer-aided design (CAD) and finite element analysis (FEA) technology, the loading frame is topologically optimized and simulated. By simulating the stress distribution and deformation under different working conditions, the structural design is optimized, unnecessary materials are removed, and the strength and stiffness requirements of the structure are guaranteed. This method can precisely control the material distribution and achieve maximum lightweight.

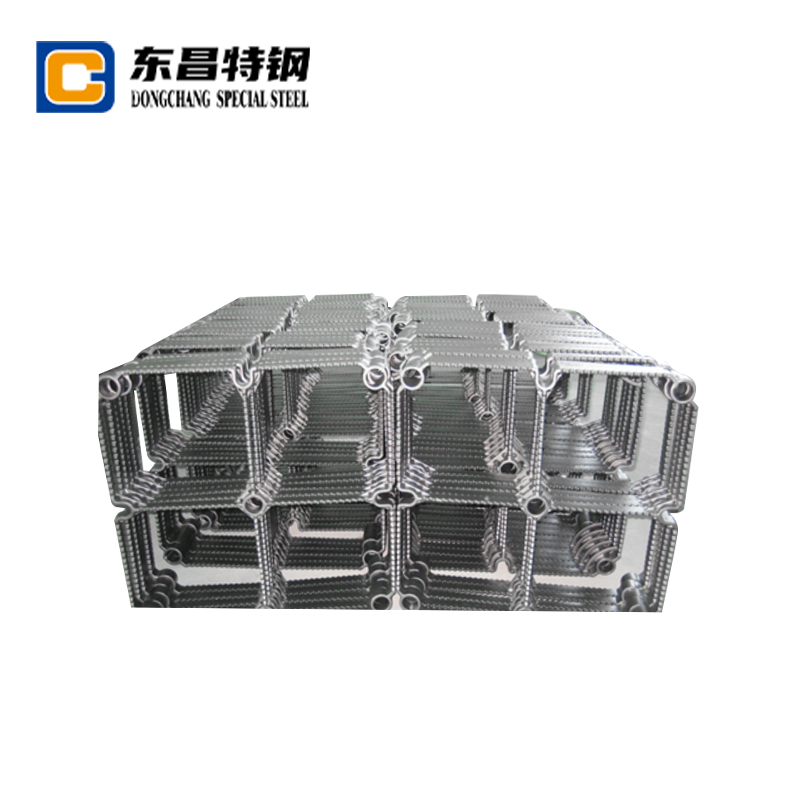

Modular and standardized design:

The modular design concept is adopted to decompose the loading frame into multiple functional modules, and each module is independently designed, manufactured and tested. This design method can not only improve production efficiency and reduce costs, but also help to achieve lightweight. At the same time, the standardized design makes different modules interchangeable and universal, further improving the flexibility and maintainability of the Heat Resistant Steel Loading Frame.

Manufacturing process improvement

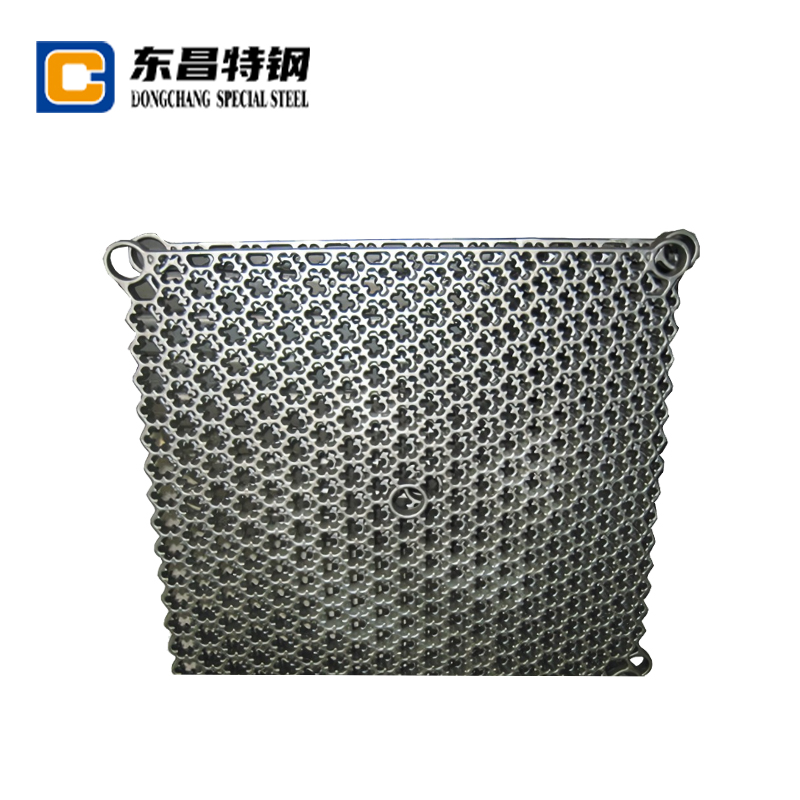

Precision machining technology:

Adopt advanced machining technologies such as high-precision CNC machine tools, laser cutting, and water cutting to improve machining accuracy and surface quality, reduce machining allowance, and thus reduce material consumption and weight. In addition, precision machining also helps to improve assembly accuracy and overall performance.

Welding and connection technology:

Optimize welding process and connection method, adopt advanced welding technology and high-performance connectors, ensure connection strength and sealing, and reduce the use of welding materials and connectors. For example, the use of high-efficiency welding technologies such as laser welding and stir friction welding can significantly reduce welding deformation and energy consumption.

Intelligence and integration

While lightweight design, focus on the intelligence and integration of the loading frame. By integrating intelligent devices such as sensors and control systems, real-time monitoring and precise control of the loading process can be achieved. This not only helps to improve energy efficiency, but also optimizes loading strategies through data analysis, further reducing energy consumption and emissions.

With the advancement of the "dual carbon" goals, Heat Resistant Steel Loading Frame has achieved significant technological innovation and improvement in lightweight design. Through the application of advanced materials, optimization of structural design, improvement of manufacturing processes, and the integration of intelligence and integration, it has achieved a significant reduction in weight while ensuring equipment performance, thereby reducing energy consumption and emissions, and making an important contribution to the green transformation of the industrial field.

English

English русский

русский Deutsch

Deutsch 中文简体

中文简体 +86-15861061878

+86-15861061878